machine tool industry

——

Shaanxi Hanjiang Machine Tool Co., Ltd. Machine tool industry is a collection of precision parts, large parts, cold work parts processing and automation precision CNC machine tool assembly as one of the integrated manufacturing industry. There are more than 500 employees, with an industrial construction area of 20000 square meters and a constant temperature area of 5000 square meters. It has more than 300 major metal cutting machine tools (including more than 50 fine, large and thin equipment), screw dynamic measuring instruments, three-coordinate and other advanced measuring instruments, with an annual production capacity of 350 sets of precision machine tools. The company has the core technology of precision thread manufacturing. With its strong R & D and manufacturing capabilities, as the project responsibility unit, it has successively undertaken three major national science and technology special projects involving thread processing equipment, promoting the company's industrial structure adjustment and independent innovation capabilities. New step.

Hanjiang Thread Grinder Research Institute (industry centralized) is the company's machine tool industry product research and development institutions, the institute consists of mechanical design room, electrical design room, process room, hydraulic room, standardization room, mechanical, electrical laboratory and other technical institutions. Existing engineering and technical personnel more than 70 people, including senior titles of technical personnel about 40 people. In recent years, it has obtained 30 utility model patents, 3 design patents and 3 invention patents in the research and development of CNC machine tools. Seven projects have passed the appraisal of provincial scientific and technological achievements, published more than 10 scientific and technological papers, completed the development of major new products and achieved more than 40 technological innovation achievements. The new products of SK7732 × 15 CNC worm grinder and SK7432 × 40 CNC screw grinder won the second prize of science and technology in Shaanxi Province, the new products of CNC worm grinder won the third prize of science and technology in China's machinery industry, and the independently developed SK7450 × 100 CNC screw grinder won the top ten innovative products in the national machine tool industry.

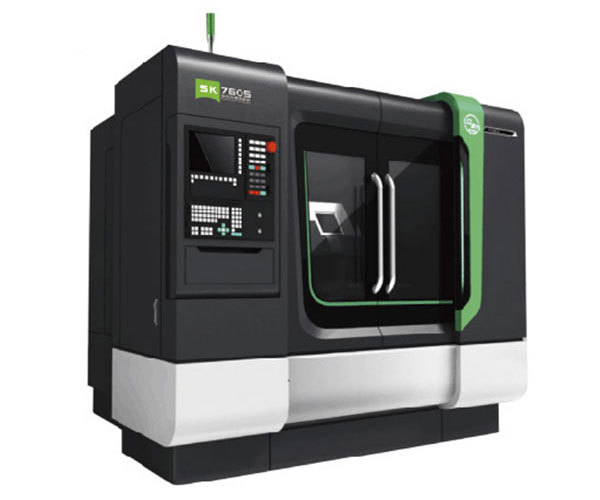

The company's machine tool industry mainly develops and manufactures complete sets of line, high-precision, high-efficiency, automated, and intelligent CNC thread processing machine tools. It has 16 series of 135 products and has the technical ability to provide users with integrated process solutions for precision thread manufacturing.

The main product series of the machine tool industry are: line/complete sets of micro ball screw processing equipment, automotive key parts screw processing equipment, precision worm processing equipment, thread ring plug gauge processing equipment, screw rotor processing equipment, complete sets of thread measuring instrument series equipment, special CNC processing equipment.

Machine tool industry series products are widely used in auto parts industry, measuring tool industry, rolling functional parts industry, reducer industry and other fields. Products are exported to the United Kingdom, Russia, Brazil, Peru, Singapore, Saudi Arabia, Indonesia, India, Iran, Turkey, Vietnam and other countries and Taiwan.

"Han machine brand" thread grinder won the title of "Shaanxi famous brand products. The company has always implemented the quality policy of "first-class products, first-class technology, first-class management, first-class service", and is willing to discuss cooperation with friends from all walks of life with the enterprise spirit of "integrity-based, excellence!

Rolling functional parts industry

——

The rolling functional components industry of Shaanxi Hanjiang Machine Tool Co., Ltd. covers several major operating branches of screw factory, guide rail factory, gear factory, Pudong branch factory and industry and trade company. The company has 1299 sets of rolling functional parts processing equipment with complete specifications, quantity and precision (including more than 800 sets of metal cutting equipment), advanced thread testing instruments and comprehensive precision testing instruments for rolling linear guide rails in the industry, and has an annual production capacity of 100000 meters of ball screw 200000 pairs and ball linear guide rails.

The main products of the rolling functional parts industry are: ball screw pair, rolling linear guide pair, rolling guide block, ball spline, ball guide sleeve, precision cross table, self-locking device, linear module, precision roller cross guide pair, Precision needle roller cross guide pair, etc.; after more than 50 years of development, in terms of output, output value, scale, research and development capability, manufacturing technology level, etc., are in the leading level of the domestic industry.

The company has a provincial rolling functional parts research institute, specializing in the development of rolling functional parts and the formulation of industry standards. The Institute consists of ball screw design and development room, linear guide design and development room, process room, technical transformation room, rolling functional parts laboratory and other technical institutions. There are more than 80 engineering and technical personnel, including 8 senior titles and 40 intermediate titles. At the same time, it has a university cooperation laboratory for basic theoretical research, "Hanjiang-South Polytechnic Rolling Functional Components Basic Theory Laboratory".

Since the 1980 s began to develop precision ball screws and rolling linear guides, through continuous introduction, digestion, absorption and independent innovation and development, we have mastered a number of core technologies. He has successively undertaken three major national science and technology projects involving functional components, one provincial science and technology project, and five participating projects. The research on new materials, new technologies and new processes of reverser, the key components of ball screw pair, has won the first prize of science and technology in Hanzhong City. 20 scientific and technological innovation projects have obtained utility model patents, published more than 20 scientific and technological papers, completed the development of major new products and achieved more than 10 technological innovation achievements.

The main products of rolling functional components are widely used in CNC machine tools, automobile manufacturing, machinery manufacturing, rail transit, metallurgy, plastic machinery and other industries and fields. High-speed, heavy-load, precision and large-scale ball screw pairs provide tens of thousands of sets of imported ball screw pairs for large and well-known domestic enterprises. Heavy-duty ball screw pairs participated in the "11th Five-Year Plan" major scientific and technological achievements exhibition; Miniature precision ball screw pairs have become designated products by many units. Roller guide rails, subway guide rails, intelligent linear guide rails and other products have replaced imports and become designated products by many customers.

The rolling function components of "Hanji brand" produced by the company have won the titles of "China's most influential famous brand" and "famous brand product of Shaanxi Province" for many times. It is a well-known brand in China. The products have been rated as "national customer satisfaction products" by the national user committee of CNC machine tools of China Quality Association for many times ".

"Chinese equipment, equipment China", in order to realize the batch localization of my country's high-end rolling functional components and meet the needs of China's high-end equipment, we are willing to discuss cooperation with colleagues from all walks of life!